Data-Based Learning for Control of Elastic Interactions Between Robot and Workpiece

Oct 8, 2019·,,,,·

1 min read

Lance McCann

Chia Ning Lee

Yoshua Gombo

Joseph Garbini

Santosh Devasia

Abstract

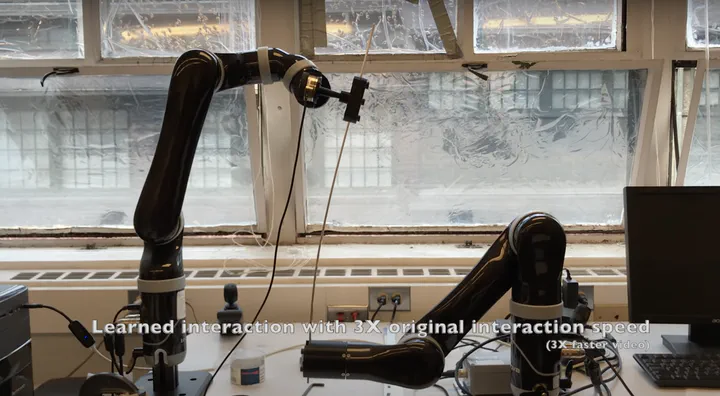

Efficient and accurate robotic interactions with flexible structures are critical for many manufacturing processes where the elasticity of the workpiece and the robot must be accounted for. In particular, for clamping and drilling flexible structures, maintaining tool-workpiece normality and limiting shear forces are essential. The main contribution of this article is to show experimentally, that data acquired during a robotic clamping operation can be used to speed up the process for similar operations. Utilizing the learned parameters, a map between the measured forces and robot joint positions is used to develop time-based robot-joint (velocity) trajectories to achieve a specified robot-workpiece interaction. Experimental results show that the operating speed can be increased by three times while maintaining interaction forces and torques within acceptable levels.

Type

Publication

ASME Dynamic Systems and Control Conference

This work is driven by the results in my previous paper on LLMs.

Create your slides in Markdown - click the Slides button to check out the example.

Add the publication’s full text or supplementary notes here. You can use rich formatting such as including code, math, and images.